We Love Stained Glass! David Gomm started building stained glass windows in 1983 and soon convinced Jeanne to join him in the art. They have become experts at many aspects of stained glass building, design and repair. Their website www.gsg-art.com has many tips and articles about stained glass, art in general and creativity.

Friday, October 28, 2016

5 Finish With Tail And Wheels

This week we revisit the instructions to creating an airplane kaleidoscope. Start with the kaleidoscope made from a mini-scope refill kit (instructions are available on our video sold on Amazon, click here for details) It's a pretty good project and the instructions can be helpful.

Thursday, October 27, 2016

4 Solder The Upper Wing In Place

This week we revisit the instructions to creating an airplane kaleidoscope. Start with the kaleidoscope made from a mini-scope refill kit (instructions are available on our video sold on Amazon, click here for details) It's a pretty good project and the instructions can be helpful.

Fourth, tack the upper wing in place and add wires to hold it in place.

Join us to receive our free weekly newsletter.

Click Here To Go To Video

Wednesday, October 26, 2016

3 Solder On The Bottom Wings

This week we revisit the instructions to creating an airplane kaleidoscope. Start with the kaleidoscope made from a mini-scope refill kit (instructions are available on our video sold on Amazon, click here for details) It's a pretty good project and the instructions can be helpful.

Third, we tack the bottom wings in place and then solder them in solidly.

Join us to receive our free weekly newsletter.

Click Here To Go To Video

Tuesday, October 25, 2016

2 Use The PDF To Build Parts

This week we revisit the instructions to creating an airplane kaleidoscope. Start with the kaleidoscope made from a mini-scope refill kit (instructions are available on our video sold on Amazon, click here for details) It's a pretty good project and the instructions can be helpful.

Second, use the PDF to cut out the parts for the bi-plane. Click here to get the PDF.

Join us to receive our free weekly newsletter.

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

Click Here To Go To Video

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

1 Start With A Mini Scope Body

This week we revisit the instructions to creating an airplane kaleidoscope. Start with the kaleidoscope made from a mini-scope refill kit (instructions are available on our video sold on Amazon, click here for details) It's a pretty good project and the instructions can be helpful.

First, we'll start with a mini scope body. This is the kaleidoscope built from the instructions above. You won't need the video if you've already built kaleidoscopes.

Join us to receive our free weekly newsletter.

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

Click Here To Go To Video

Kaleidoscope Becomes An Airplane

This week we revisit the instructions to creating an airplane kaleidoscope. Start with the kaleidoscope made from a mini-scope refill kit (instructions are available on our video sold on Amazon, click here for details) It's a pretty good project and the instructions can be helpful.

Join us to receive our free weekly newsletter.

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

Click Here To Go To Video

Thursday, October 20, 2016

5- Rock The Glass Apart!

Our New Five Steps video is about building a Jig. I felt that the clip I put up a few weeks ago touched on this but not in enough depth.

The 5th step in Jig building is to rock the glass apart. (score it first)

ALL DONE!

Join Our Email List

4-Mark Where The Bevel Is Cut

Our New Five Steps video is about building a Jig. I felt that the clip I put up a few weeks ago touched on this but not in enough depth.

The 4th step in Jig building is to mark where to cut the bevel. Place it on the pattern, use a marker to trace where the bevel should be cut and mark the glass.

Join Our Email List

Wednesday, October 19, 2016

3-Use Strip Cutter to Determine Where Strips Go

Our New Five Steps video is about building a Jig. I felt that the clip I put up a few weeks ago touched on this but not in enough depth.

The 3rd step in Jig building is to use the strip cutter to figure where the strips should go. Then mark them, cut them to length and place them on the jig.

This is important, make sure they are placed so that the bevel sits exactly where you want it cut. If it gets turned around, you want it to fall in the same place.

Join Our Email List

Monday, October 17, 2016

2- Cut 2 -1/8" Thick Wood Strips

Our New Five Steps video is about building a Jig. I felt that the clip I put up a few weeks ago touched on this but not in enough depth. The 2nd step in Jig building is to cut 2 -1/8" thick wood strips to be used as guides for setting glass in the jig.

About 1/2" wide will be good. Clip the corners off the strips so the head of the strip cutter can get closer to the edge of the glass.

Join Our Email List

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

1-Start With A Board And A Wood Strip

Our New Five Steps video is about building a Jig. I felt that the clip I put up a few weeks ago touched on this but not in enough depth. The 1st step in Jig building is to Start with A Board And A Wood Strip.

A 12 X 12 piece of plywood and a 3/4" X 1-1/2" piece of pine usually work well for me. You nail the wood strip to the board to use as a cleat which will guide your strip cutter.

Join Our Email List

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

Friday, October 07, 2016

You Tube Channel Is Growing

Today while doing some work on You Tube, I saw that we now have 1008 subscribers to our You Tube Channel. This seems a far cry from the 50 or so subscribers to this blog.

We currently have 68 videos on our YouTube channel. That will change shortly. We've been working with a firm to increase traffic to our website and they are just putting the finishing touches to 25 videos they've been working on for us. We expect them to be published some time next week. This should help us to get our love of stained glass message out to the world.

You know, we love all things stained glass and all things creative. As we approach the publication date of Jeanne's second Mandala book, we hope to meet more people and introduce them to the happiness and healing that can be found through stained glass.

Visit us at www.gsg-art.com, read the articles, view the creativity slideshow, and join our email list. We welcome your thoughts and insights as we share our love for the colorful art of stained glass.

Thursday, October 06, 2016

5 Replace New Piece into The Panel

This week We put up a video which is five steps to doing a simple straight forward stained glass repair.

This fifth step is place the glass into the opening. We put a piece of scrap glass under so it sit's flush with the other glass. Then we solder in the piece, turn over the panel and solder the other side, after which we clean, patina and polish the repair which should look exactly like it did originally.

To Get Additional Videos That We Don't Post To YouTube Sign Up Here

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

To View the video click here

4 Cut The Replacement Glass

This week We put up a video which is five steps to doing a simple straight forward stained glass repair.

This fourth step is to cut, grind and fit the replacement glass. It doesn't have to be perfect. Remember that when building a panel you leave a little wiggle room, the same can be true with a repair.

To Get Additional Videos That We Don't Post To YouTube Sign Up Here

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

To View the video click here

3 Tap and Remove The Glass

This week We put up a video which is five steps to doing a simple straight forward stained glass repair.

This third step is to tap and remove the broken or damaged piece of glass. We do this gently so as not to damage the surrounding foil on adjacent pieces of glass.

Then as we remove the copper foil, we are careful to only remove the inner circle of foil.

To Get Additional Videos That We Don't Post To YouTube Sign Up Here

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

To View the video click here

Tuesday, October 04, 2016

2 Heat Up Your Soldering Iron

This week We put up a video which is five steps to doing a simple straight forward stained glass repair.

This second step is to heat up your soldering iron so you can desolder the metal around the damaged piece of glass.

To Get Additional Videos That We Don't Post To YouTube Sign Up Here

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

To View the video click here

Monday, October 03, 2016

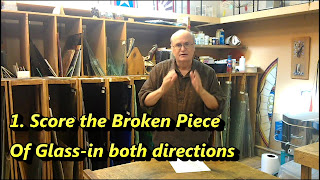

1 Score The Bad Piece

This week We put up a video which is five steps to doing a simple straight forward stained glass repair.

This first step is to cut and score the broken or damaged piece of glass. We do this in both directions so the glass will be easy to remove.

Some students have asked if they could try to save the glass by de-soldering without scoring the glass. This can be done, but we're a production studio, which means that we need to get results quickly and the extra time and effort of saving a piece may not be worth it.

To Get Additional Videos That We Don't Post To YouTube Sign Up Here

Success! Thanks For Joining Us!

Check your email to confirm your subscription. And get our Thanks For Joining PDF with video link.

Look for a zip file attached to the confirmation.

Usually a little box in the lower left hand corner of the screen.

To View the video click here

Subscribe to:

Posts (Atom)